About

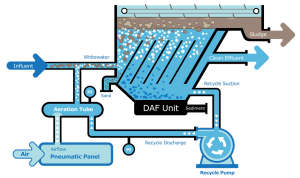

A-Pro is gravity separation process where by the separation of two phases is achieved by increasing the specific gravity difference of the two phases. This is achieved by attaching micro air bubbles, brought about by saturating water with air under pressure, and then expanding the water stream through valves to atmospheric pressure. These micro bubble nucleate into the solid particles to be separated, thus lowering the specific gravity and allowing contaminants to rise the surface.

Process

Dissolved air flotation (A-Pro) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causingthe suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Applications

- Poultry Processing, Meat Processing and Packing

- Dairy Processing Unit

- Fish Processing

- Mining Industry

- Petro-Chemical Industry

- Textile Industry

- Tanneries, Other Industry

- Pulp and Paper Industry

Advantages

- High loading rate: Typically 10-20m/h. New process variants have operated success fully up to 40-45m/h.

- Very thick float (sludge) product: Typically 2-3% total solids float can be achieved using hydraulic or mechanical skimming devices. Float can be de watered without intermediate thickening.

- Often, no polymer is required, as DAF does not require a large, dense floc. Coagulant dosages may also be reduced in some circumstances.

- Excellent algae removal efficiencies.

- Smaller footprint required as compared to conventional flocculation and gravity sedimentation.